Fanless Mini PC achieves efficient heat dissipation by optimizing heat dissipation structure, material selection and intelligent temperature control technology. The following are specific implementation methods and technical points:

1. Core heat dissipation principle

- Passive heat dissipation design

It completely relies on thermal conductive materials (such as aluminum alloy and copper) to transfer internal heat to the outer shell, and dissipates heat through natural convection or radiation, without active heat dissipation components.

Typical case: France's Bleu Jour KUBB Fanless Gen2 uses an aluminum fin body and achieves silent heat dissipation through precision-machined heat sinks.

The heat from heat sources such as CPU is quickly transferred to the heat sink or outer shell by using the liquid evaporation-condensation cycle in the heat pipe to improve heat dissipation efficiency.

Common in industrial tablet computers, such as aluminum alloy body combined with heat pipe technology to achieve efficient heat transfer.

- Natural convection optimization

Promote air flow through the outer shell air duct design (such as heat dissipation fins and vents), and achieve heat dissipation by using the principle of hot air rising and cold air sinking.

2. Key technical means

- Application of high thermal conductivity materials

Aluminum alloy/copper shell: quickly absorb internal heat and disperse it to the entire body, such as industrial tablet computers use fully enclosed aluminum alloy shells to improve heat dissipation performance.

Thermal paste filling: fill the microscopic air gap between the CPU and the radiator, reduce thermal resistance, and improve heat conduction efficiency.

- Heat dissipation structure optimization

Heat dissipation fins: increase the surface area to accelerate heat dissipation, such as the aluminum fin design of KUBB Gen2.

Low-power components: use low-power processors (such as Intel N series) to reduce heat generation and reduce heat dissipation pressure.

- Intelligent temperature control technology

Real-time monitoring of device temperature through temperature sensors, dynamic adjustment of CPU load or reduction of operating frequency to avoid overheating.

3. Design optimization and precautions

- Internal layout and component distribution

Evenly distribute heat-generating components to avoid local overheating (such as keeping memory and hard disk away from the CPU).

"Heat source dispersion + heat dissipation concentration" design is common in industrial equipment, such as heat pipes directly connected to the shell heat dissipation area.

- External environment adaptation

Dusty/humid environment: Fully enclosed design prevents dust from entering, relies on metal shell for heat conduction, and avoids the risk of fan blockage.

High-load scenario: It is necessary to limit long-term high-load operation, or use advanced solutions such as liquid cooling to assist heat dissipation (such as high-performance models).

Avoid blocking the device's heat dissipation holes to ensure natural convection.

High-heat components (such as M.2 solid-state drives) can be equipped with heat dissipation vests or independent heat dissipation modules.

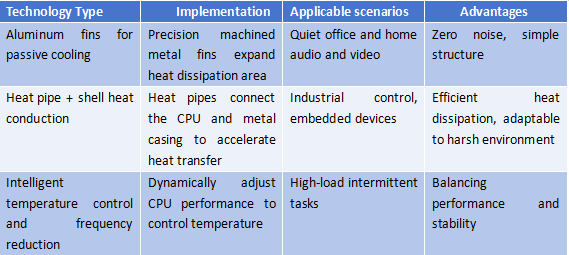

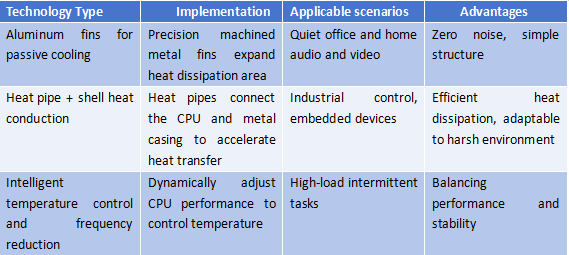

4. Comparison of typical heat dissipation solutions

Through the above technical combination, fanless Mini PCs can strike a balance between quietness, durability and heat dissipation efficiency, especially suitable for noise-sensitive or harsh environments.